CRYOGEN CABINETS

The previous situation, marked by the health emergency linked to COVID-19, led us to look for a tailor-made technological solution for the storage of vaccines developed to combat the virus. Indeed, to preserve their effectiveness, these vaccines must be stored and maintained at a minimum temperature of -70°C.

The technological solution for storage optimization we have achieved through the implementation of cryogenic cabinets, i.e. of the Cryo Cabinet , powered by liquid nitrogen.

The Cryo Cabinet can be used to store and maintain at temperature not only food products but also pharmaceutical products, such as medicines and vaccines. It has been designed to maintain a temperature of -90 ° and allow complete insulation thanks to solvent-free and CFC-free foams.

Thanks to the dry ice, which we produce, which has a temperature of – 78.5 °, the vaccines can be placed in special containers, and be properly transported, so as not to interrupt the cold chain, and to always maintain the optimal temperature, from the moment they are produced, until their inoculation.

MEC is able to meet the significant demand linked to this urgent need, both with the tailor-made creations of Cryo Cabinet for the storage of vaccines, and with the supply of dry ice, for their transport .

MEC is able to produce Cryo Cabinet for both the food and pharmaceutical and industrial sectors.

Our Cryo Cabinets intended for the food sector are built with materials that comply with the MOCA (Food Contact Object Material) Certification. This is a specific certification for materials and components that come into contact with food; which must not transmit or transfer substances that can contaminate the food placed in freezing. For this reason, the materials are certified by the laboratories, following particular procedures of immersion in particular solutions of basic acids, subsequently any releases of heavy metals are analyzed, a dangerous factor if placed in contact with food that must be consumed. MEC, for food construction

USE ONLY CERTIFIED MATERIALS and therefore our CRYO CABINETS are CERTIFIED and can be used in the food sector.

Unit suitable for crusting and freezing, with nitrogen in the liquid phase, solid and semi-dense or liquid products in the sectors: food, pharmaceutical, industrial . It can also be used as a pre-freezer to help with gaseous or mechanical freezing tunnels. The great simplicity of regulation of the crusting unit allows it to be used for multiple products to be frozen. The process consists in crusting or freezing a product, especially food-grade, by putting it in contact with a cryogenic fluid film, inside a vibrating container with linear movement (vibrating screen type).

As a result of the calefaction phenomenon, the food products, although very sticky, do not adhere absolutely to the support or to each other. In addition, the direct contact between the products and the cryogenic fluid at an extremely low temperature allows an almost immediate freezing of the surface of the product itself. The cryogenic fluid consists of a non-toxic, non-harmful and inert gas , whose boiling point is -196 ° C and is liquid nitrogen. The vibrating tank, in which the liquid nitrogen is contained, is moved by vibrators, whose frequency varies according to the speed to be given to the treated product, or to the contact time between the product and the cryogenic fluid itself. The contact time, which can be adjusted according to the angle between the direction of the vibratory movement and the surface of the tank, the length of the tank itself and its inclination, is on average between 10 and 15 sec.

A recirculation system, created by means of a collection tank and a cryogenic pump, allows the reuse of liquid nitrogen until it is exhausted . The quantity of cryogenic fluid evaporated during the freezing process is evacuated from the operating area by means of a suction hood and relative transfer fan.

Working cycle

1. Filling the process tank with the liquid nitrogen with the feeding from the storage tank (automatic).

2. Manual adjustment of the operating parameters: valve of the liquid nitrogen pump flow rate, frequency of the inverter of the vibrators to vary the speed of advancement of the product, exit of the rod of the jacks to vary the inclination of the tank and its relative thickness, of liquid nitrogen.

3. Arranging temperature of the unit with liquid nitrogen circulation only for 10 minutes.

4. Feeding of the product to be crusted.

5. End of feeding of the product to be crusted.

6. After 2 minutes, liquid nitrogen supply is interrupted.

7. After 60 sec. interruption of all unit functions and discharge of liquid nitrogen from the process tank.

8. When the temperature of the unit has returned to that of the environment, cleaning and washing can be carried out if necessary

Features

Suitable for trolleys: 600 x800x h 1800

Specific for pharmaceutical and meat applications

Suitable for freezing foodstuffs

Monobloc cell to facilitate cleaning

Cell and / or product temperature control

Door with anti-entrapment system for operators

Technical features

Power supply – Two versions: Liquid nitrogen (N2L) / Carbon dioxide (CO2)

Temperature – Operating temperature down to -70 ° C

Insulation – Insulation with solvent and CFC free foams

Accessories – Accessories and special applications on request

Technical data

Diagonal pieces< 100 mm

Liquid nitrogen film thickness approx. 5 mm

Vibration frequency 40/60 Hz

Movement range 0.3 / 15 mm

Tilt angle -2 ° / + 4 °

Contact time< 15 sec

Plant productivity

During practical tests carried out in collaboration with customers we have obtained extremely interesting results especially when compared with the compact dimensions of the equipment.

Liquid nitrogen film thickness approx. 5 mm

Apple cubes 1,000 kg / h

Lentils 720 kg / h

Berries 250 kg / h

Strawberries 180 kg / h

Slices of kiwi 600 kg / h

Boiled rice 850 kg / h

Unit suitable for crusting and freezing, with nitrogen in the liquid phase, solid and semi-dense or liquid products in the sectors: food, pharmaceutical, industrial . It can also be used as a pre-freezer to help with gaseous or mechanical freezing tunnels. The great simplicity of regulation of the crusting unit allows it to be used for multiple products to be frozen. The process consists in crusting or freezing a product, especially food-grade, by putting it in contact with a cryogenic fluid film, inside a vibrating container with linear movement (vibrating screen type).

As a result of the calefaction phenomenon, the food products, although very sticky, do not adhere absolutely to the support or to each other. In addition, the direct contact between the products and the cryogenic fluid at an extremely low temperature allows an almost immediate freezing of the surface of the product itself. The cryogenic fluid consists of a non-toxic, non-harmful and inert gas , whose boiling point is -196 ° C and is liquid nitrogen. The vibrating tank, in which the liquid nitrogen is contained, is moved by vibrators, whose frequency varies according to the speed to be given to the treated product, or to the contact time between the product and the cryogenic fluid itself. The contact time, which can be adjusted according to the angle between the direction of the vibratory movement and the surface of the tank, the length of the tank itself and its inclination, is on average between 10 and 15 sec.

A recirculation system, created by means of a collection tank and a cryogenic pump, allows the reuse of liquid nitrogen until it is exhausted . The quantity of cryogenic fluid evaporated during the freezing process is evacuated from the operating area by means of a suction hood and relative transfer fan.

Working cycle

1. Filling the process tank with the liquid nitrogen with the feeding from the storage tank (automatic).

2. Manual adjustment of the operating parameters: valve of the liquid nitrogen pump flow rate, frequency of the inverter of the vibrators to vary the speed of advancement of the product, exit of the rod of the jacks to vary the inclination of the tank and its relative thickness, of liquid nitrogen.

3. Arranging temperature of the unit with liquid nitrogen circulation only for 10 minutes.

4. Feeding of the product to be crusted.

5. End of feeding of the product to be crusted.

6. After 2 minutes, liquid nitrogen supply is interrupted.

7. After 60 sec. interruption of all unit functions and discharge of liquid nitrogen from the process tank.

8. When the temperature of the unit has returned to that of the environment, cleaning and washing can be carried out if necessary

Features

Pass-through double-cell cabinet with four doors.

Two cells with independent controls.

Operation with N2L or liquid CO2.

Minimum temperature at – 75 °.

“Food grade” construction according to CE standards.

Double function: cryogenic cell for freezing food and door between the kitchen department and the packaging department (anti-contamination between two departments).

Compatible with standard trolleys 600 x 800 x h. 1,800 mm [: en]

Technical data

Diagonal pieces< 100 mm

Liquid nitrogen film thickness approx. 5 mm

Vibration frequency 40/60 Hz

Movement range 0.3 / 15 mm

Tilt angle -2 ° / + 4 °

Contact time< 15 sec

Plant size

The plant on which the productivity data were collected and which we propose as a standard are:

Liquid nitrogen film thickness approx. 5 mm

Overall dimensions 2.000 × 1.600 × 1.300 mm

Nitrogen tank dimensions 1,500 × 1,000 mm

Plant productivity

During practical tests carried out in collaboration with customers we have obtained extremely interesting results especially when compared with the compact dimensions of the equipment.

Liquid nitrogen film thickness approx. 5 mm

Apple cubes 1,000 kg / h

Lentils 720 kg / h

Berries 250 kg / h

Strawberries 180 kg / h

Slices of kiwi 600 kg / h

Boiled rice 850 kg / h

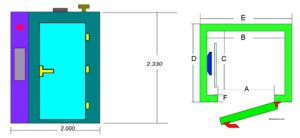

“MGM” model, designed to contain 1 trolley 600 × 800 mm

Structure

Exterior : 304L stainless steel, satin finish, thickness 1.5mm

Interior : 304L stainless steel, 2B finish, 1.5mm thickness

Construction : 304L stainless steel structure

Entrance : A folding slide is fixed in the door jamb. The slope allows easy access of the trolleys in the freezer.

Welding : Internal and external fully TIG welded, in compliance with HACCP standards.

Lifting eyebolts : The freezer roof is equipped with 4 slightly curved stainless steel fins 10 mm thick with a hole of suitable size for connecting the belts for lifting by crane.

Bumper : A tubular bumper is installed in the rear wall of the freezer, approximately 1,000 mm from the floor. This bumper is designed to stop the trolley and prevent it from hitting the back wall.

Dimensions

Removable parts (extraction collar, bumper, eyebolts, etc.) are not included in the dimensions shown. Dimension Tolerances: +/- 5mm or 2%.

A: 800 mm B: 1,360 mm

C: 1,250 mm D: 1,500 mm

E: 1,600 mm F: 120 mm

Weight: 870 kg

Isolation

Walls / door : the thermal insulation is made with polyurethane foam (CFK free), and an average density of about 50 kg / m³, and class E. Thickness 120mm, conductivity factor λD = 0.021 W / mK.

Floor : The floor is made of 2 3 mm thick stainless steel sheets, between which a PU panel is placed. The interior is reinforced with spacers of insulating material.

Closing the door

The door is equipped for opening with the following components:

– Stainless steel hinges

– Lacquered aluminum handle.

– Closing hinges in composite material + lacquered aluminum.

An additional safety handle (stainless steel) is installed inside the cabinet allowing exit in case of emergency. The handle, locks and hinges are designed to be used and cleaned in a food environment with moderately aggressive agents (IAA directive).

Ventilation

The fan blades are installed to draw air through the center of the fan, and to blow the gas through the opening near the deflector. The nitrogen or CO2 injection points are installed near the fan blades and are oriented in the direction of the air flow. The fan motors are protected by stainless steel sheets.

Motors : 3 motors in the MGM model cabinet (6 motors in the MPM model) of 0.75kW – 1450 rpm. 19 mm Ø shaft, stainless steel shaft extension (36 mm Ø), standard B5 flanges

Blades : 5-blade HasconWings (TM440 / 5-5 ° / MD / PAG / Rot D / LDD F3D), diameter 450 mm, core material aluminum

Deflector : The deflector is fixed to the cabinet wall, but can be easily disassembled for maintenance or special cleaning operations

Safety : The engines stop when the stop is pressed. The door opens completely only after a preset delay that allows the complete stop of the ventilation motors. The door can be opened from the inside in case an operator gets trapped in it . To facilitate this operation, the door is equipped with a handle that allows it to be opened easily and instinctively by pushing it outwards.

Spray system for different gases

N2 injection: the gas injection is carried out with a spray ramp mounted inside the freezer that descends to the sides of the fans in the shape of an inverted U. (two ramps in the case of MPM cryobox). The liquid / gas transformation takes place through calibrated holes obtained on the two descending arms of the spray ramp and made in such a way as to be able to distribute the gas on all levels of the trolleys in a uniform way. The manifold of the two spray ramps is installed inside the box.

CO2 injection: gas injection and carbon snow spray are carried out through a multiple system with a spray point at each fan. The spray system is for the most part external to the cabinet, it is made of stainless steel and is duly insulated. A cryogenic valve that regulates the passage of gas corresponds to each spray point.

Link to checkout

The extraction of the exhaust gas is obtained by overpressure, through an opening in the roof of the freezer.

– Diameter D206 – D200 (external – internal) mm

– Collar diameter D206 mm x H100 mm, removable

If an extraction fan is installed on the freezer for forced gas extraction, its diameter should be at least 300 mm, to avoid obstructions or resistance to natural ventilation in the event that this fan does not work properly. An extraction fan can create a vacuum inside the cabinet, making it difficult to open the door. When the door is opened, the gases inside flow outwards.

Cabinet

The electrical components are grouped together in an electrical cabinet. This is installed on the same side as the motorized fans. A door guarantees accessibility to the components. This door is closed with a triangular key lock.

– AISI 304 carpentry

– IP55 class

– Power supply 3 x 400V + T + PE 50 Hz (+/- 5%)

– The door has a triangular key lock. It is sealed with a rubber gasket

– Transformer 220V / 24VDC, 150VA

– CE IIA certified

Control panel

Temperature control :

– Thermoregulator for 1 set of freezing parameters that controls the chamber temperature

– Thermoregulator for 1 set of freezing parameters that controls the temperature at the core of the product

– Spray pause timer for cryogen injection.

– Cycle duration timer

Timer to set the ventilation time at the end of the cycle

Alternative : PLC for the management of preset recipes

Protection : IP55

The type, model and brand of the components is chosen by MEC, unless specific requests are ordered in advance by the customer .

Additional accessories

Pt100 product temperature probe that manages the process not with the chamber temperature, but with the core temperature of the product.

Safety

Freezers must not work in environments without monitoring devices, which check the composition of the atmosphere in the environment. These sensors are not included in the system and must be purchased and installed by specialized companies in accordance with current legislation.

Certifications and documentation

The cabinet is supplied with a user manual in Italian. The cabinet is designed and built in compliance with the CE directives. The following documents are also provided:

- CE declaration

- User Manual

- Instruction manual

- List of recommended spare parts

- Notes on maintenance

- Safety symbols

- Safety instructions with cryogenic equipment

The machine is built in accordance with the following European directives:

- Machinery Directive 2006/42 CE

- European directive 1935/2004 on materials for food applications

- EN13371 cryogenic vessels – Couplings for cryogenic use

- EN13648-1 cryogenic vessels – Safety devices for protection against overpressures

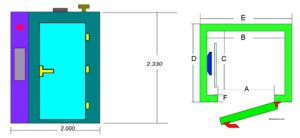

“MPM” model, designed to contain 2 trolleys with dimensions of 600 × 800 mm

Structure

Exterior : 304L stainless steel, satin finish, thickness 1.5mm

Interior : 304L stainless steel, 2B finish, 1.5mm thickness

Construction : 304L stainless steel structure

Entrance : A folding slide is fixed in the door jamb. The slope allows easy access of the trolleys in the freezer.

Welding : Internal and external fully TIG welded, in compliance with HACCP standards.

Lifting eyebolts : The freezer roof is equipped with 4 slightly curved stainless steel fins 10 mm thick with a hole of suitable size for connecting the belts for lifting by crane.

Bumper : A tubular bumper is installed in the rear wall of the freezer, approximately 1,000 mm from the floor. This bumper is designed to stop the trolley and prevent it from hitting the back wall.

Dimensions

Removable parts (extraction collar, bumper, eyebolts, etc.) are not included in the dimensions shown. Dimension Tolerances: +/- 5mm or 2%.

A: 800 mm B: 1,360 mm

C: 1,850 mm D: 2,100 mm

E: 1,600 mm F: 120 mm

Weight: 1,270 kg

Isolation

Walls / door : the thermal insulation is made with polyurethane foam (CFK free), and an average density of about 50 kg / m³, and class E. Thickness 120mm, conductivity factor λD = 0.021 W / mK.

Floor : The floor is made of 2 3 mm thick stainless steel sheets, between which a PU panel is placed. The interior is reinforced with spacers of insulating material.

Closing the door

The door is equipped for opening with the following components:

– Stainless steel hinges

– Lacquered aluminum handle.

– Closing hinges in composite material + lacquered aluminum.

An additional safety handle (stainless steel) is installed inside the cabinet allowing exit in case of emergency. The handle, locks and hinges are designed to be used and cleaned in a food environment with moderately aggressive agents (IAA directive).

Ventilation

The fan blades are installed to draw air through the center of the fan, and to blow the gas through the opening near the deflector. The nitrogen or CO2 injection points are installed near the fan blades and are oriented in the direction of the air flow. The fan motors are protected by stainless steel sheets.

Motors : 3 motors in the MGM model cabinet (6 motors in the MPM model) of 0.75kW – 1450 rpm. 19 mm Ø shaft, stainless steel shaft extension (36 mm Ø), standard B5 flanges

Blades : 5-blade HasconWings (TM440 / 5-5 ° / MD / PAG / Rot D / LDD F3D), diameter 450 mm, core material aluminum

Deflector : The deflector is fixed to the cabinet wall, but can be easily disassembled for maintenance or special cleaning operations

Safety : The engines stop when the stop is pressed. The door opens completely only after a preset delay that allows the complete stop of the ventilation motors. The door can be opened from the inside in case an operator gets trapped in it . To facilitate this operation, the door is equipped with a handle that allows it to be opened easily and instinctively by pushing it outwards.

Spray system for different gases

N2 injection: the gas injection is carried out with a spray ramp mounted inside the freezer that descends to the sides of the fans in the shape of an inverted U. (two ramps in the case of MPM cryobox). The liquid / gas transformation takes place through calibrated holes obtained on the two descending arms of the spray ramp and made in such a way as to be able to distribute the gas on all levels of the trolleys in a uniform way. The manifold of the two spray ramps is installed inside the box.

CO2 injection: gas injection and carbon snow spray are carried out through a multiple system with a spray point at each fan. The spray system is for the most part external to the cabinet, it is made of stainless steel and is duly insulated. A cryogenic valve that regulates the passage of gas corresponds to each spray point.

Link to checkout

The extraction of the exhaust gas is obtained by overpressure, through an opening in the roof of the freezer.

– Diameter D206 – D200 (external – internal) mm

– Collar diameter D206 mm x H100 mm, removable

If an extraction fan is installed on the freezer for forced gas extraction, its diameter should be at least 300 mm, to avoid obstructions or resistance to natural ventilation in the event that this fan does not work properly. An extraction fan can create a vacuum inside the cabinet, making it difficult to open the door. When the door is opened, the gases inside flow outwards.

Cabinet

The electrical components are grouped together in an electrical cabinet. This is installed on the same side as the motorized fans. A door guarantees accessibility to the components. This door is closed with a triangular key lock.

– AISI 304 carpentry

– IP55 class

– Power supply 3 x 400V + T + PE 50 Hz (+/- 5%)

– The door has a triangular key lock. It is sealed with a rubber gasket

– Transformer 220V / 24VDC, 150VA

– CE IIA certified

Control panel

Temperature control :

– Thermoregulator for 1 set of freezing parameters that controls the chamber temperature

– Thermoregulator for 1 set of freezing parameters that controls the temperature at the core of the product

– Spray pause timer for cryogen injection.

– Cycle duration timer

Timer to set the ventilation time at the end of the cycle

Alternative : PLC for the management of preset recipes

Protection : IP55

The type, model and brand of the components is chosen by MEC, unless specific requests are ordered in advance by the customer .

Additional accessories

Pt100 product temperature probe that manages the process not with the chamber temperature, but with the core temperature of the product.

Safety

Freezers must not work in environments without monitoring devices, which check the composition of the atmosphere in the environment. These sensors are not included in the system and must be purchased and installed by specialized companies in accordance with current legislation.

Certifications and documentation

The cabinet is supplied with a user manual in Italian. The cabinet is designed and built in compliance with the CE directives. The following documents are also provided:

- CE declaration

- User Manual

- Instruction manual

- List of recommended spare parts

- Notes on maintenance

- Safety symbols

- Safety instructions with cryogenic equipment

The machine is built in accordance with the following European directives:

- Machinery Directive 2006/42 CE

- European directive 1935/2004 on materials for food applications

- EN13371 cryogenic vessels – Couplings for cryogenic use

- EN13648-1 cryogenic vessels – Safety devices for protection against overpressures