CRYOGENIC PAINT STRIPPING

What is the cryogenic paint stripping process applied to?

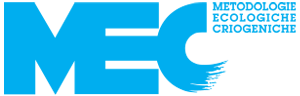

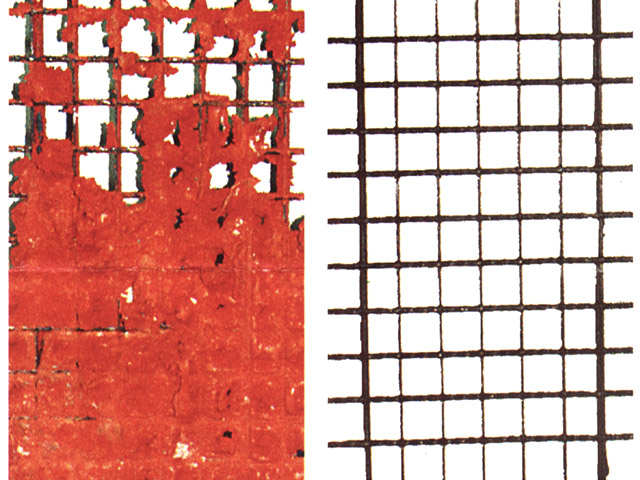

Cryogenic paint stripping is carried out on frames, grids, racks, chains, skids, and in general all the supports used in industrial painting lines.

How does the cryogenic paint stripping process take place?

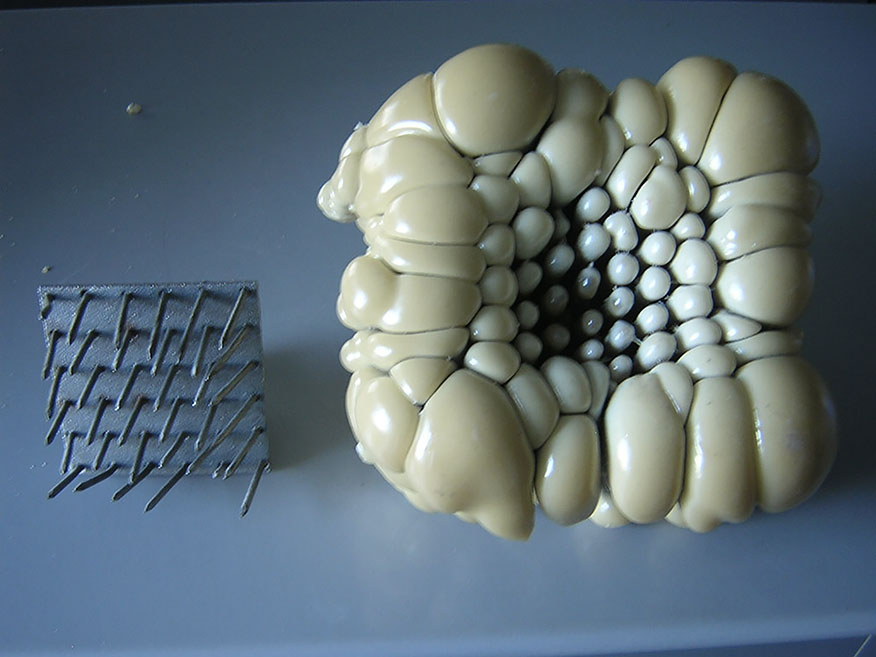

The cryogenic paint stripping process is based on the high cooling rate of liquid nitrogen. The piece to be stripped is immersed in a tank of liquid nitrogen at a temperature of -196 ° C. This involves a dimensional contraction: the paint to be removed contracts about 8 times more than the metal support on which it is applied. The splits and cracks allow the detachment from the support with a light mechanical action applied subsequently. The piece is perfectly clean, ready to be put back into production again.

What are the advantages of cryogenic paint stripping?

We certify that the cryogenic paint stripping residues are disposed of at our sole expense, in accordance with current waste regulations.

We guarantee that our process will not alter the shape or the metallurgical structure of the substrate.

This paint stripping method guarantees a longer life to the supports, without any problems for painting and for managing the painting systems.

The cryogenic paint stripping method is particularly important from the point of view of environmental protection and waste disposal.